compactPRESS ecoLINE

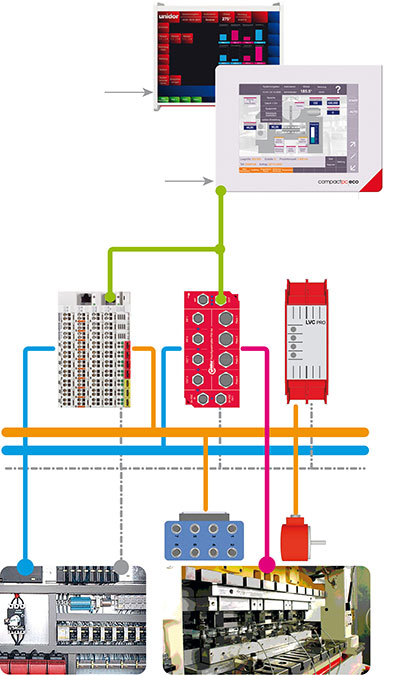

ecoline is the ideal first Stepp into the compactPRESS technology with touch Display and embedded PC. The link between sensors/actuators and ecoline is effectedvia EtherCAT terminals in the Ethernet. EtherCAT ensures the very high-speed digital and analog I/O signal transportas the basis for highly dynamic process handling. The number of I/O terminals, i.e. the number of sensors andactuators, can be scaled as required.

|

That is compactPRESScompact-press is your all-round assistant for practically everything, a professional for measuring, controlling and rationalising compactPRESS protects your machines and dies, ensures regular maintenance and service, manages, monitors and archives all compactPRESS offers simple touch-pad operation that everyone understands from the beginning. Icons instead of buttons guide compactPRESS is based on an extremely reliable IPC. The best solution for continuous under the rough conditions near the machine. compactPRESS is based on an extremely reliable IPC. The best solution for continuous under the rough conditions compactPRESS displays what is going on in the machine and directly at the machine or via e central control panel. compactPRESS understands all analog or digital sensors and combines them as you require – functionally, compactPRESS as a stand-alone system preferably for retrofitting or as a PLC sub-system of a controller as compactPRESS increases the availability of machine and die and ensures increased availability of data, |