powerPRESS

|

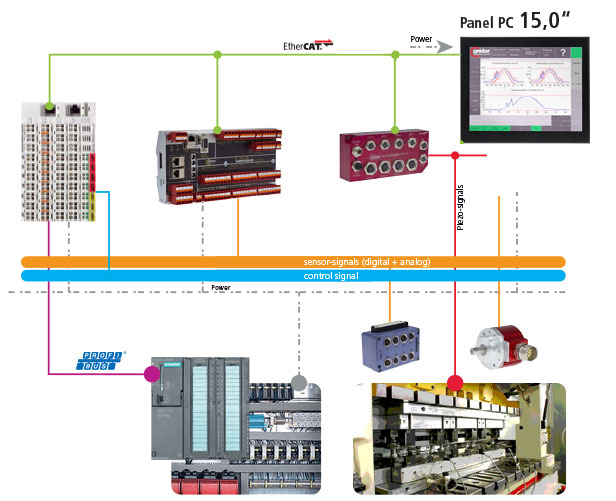

powerPRESS automates the complete machine: From the PLC (S7) through to the high-speed process monitoring with compactPRESS. The complete automation solution from a single source, the technical and economical alternative. powerPRESS is the ideal automation system for OEMs (machine and plant engineering) and for all companies machine who refurbish machines. powerPress is the first choice for modernisations, all you need for the electrical equipment is contained in this complete automation package. Not only is compactPRESS suited to retrofitting, it is perfectly suited to original equipment. |

powerPRESS combines the operation, control (PLC) and drive of machine with the measuring and quality technology of dies to form a complete machine automation solution.

Such a perfectly balanced automation of punches and presses is not only a technical trendsetter, but also economically highly attractive.

Everything comes together in the compactPRESS all-in-one automation concept: The user-friendly touch-display operation, the sturdy IPC and decentral easy-to-install I/O terminals, powerPRESS takes care of the whole machine and die – everything from a single source.

Nevertheless, the know-how of the control system and the whole automation of the machine remain under you control. You can still respond quickly and selectively to the needs of your customers and the market – independently of us.

powerPRESS for modernisation

powerPRESS is the first choice for modernisation, because the future oriented automation of punches and presses demands not only a modern control concept for the machine, but also extensive monitoring of the production process.compactPRESS is both.

powerPRESS and more

For the communication between PLC and compactPRESS, we supply a range of ready-to-use PLC data modules that you can quickly and easily integrate into your programs.From the PLC planning through to the complete control cabinet, we supply a service package for powerPRESS individually coordinated with you.